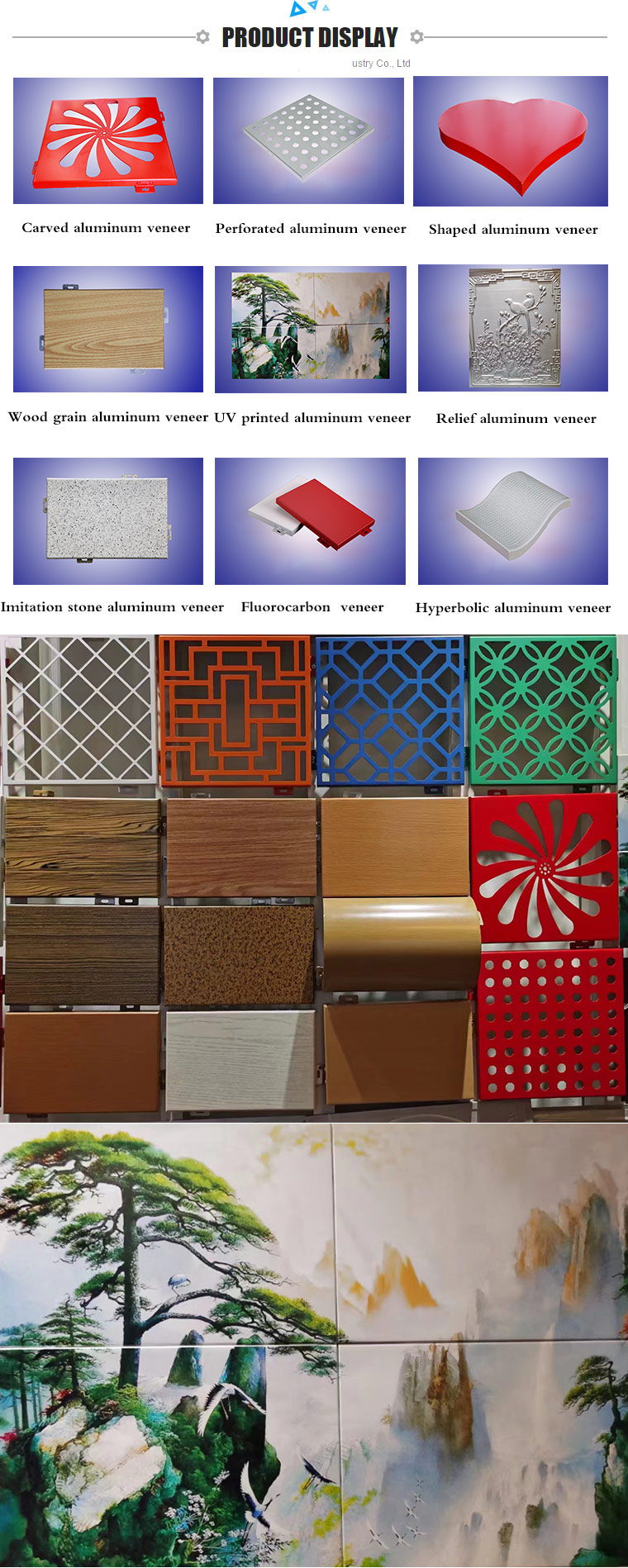

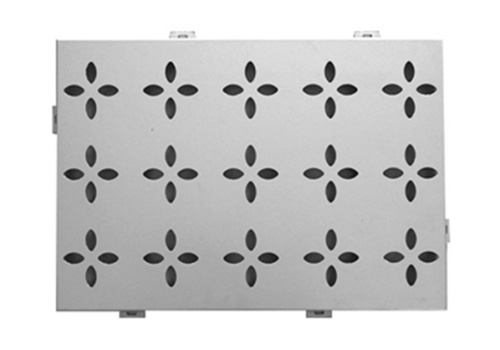

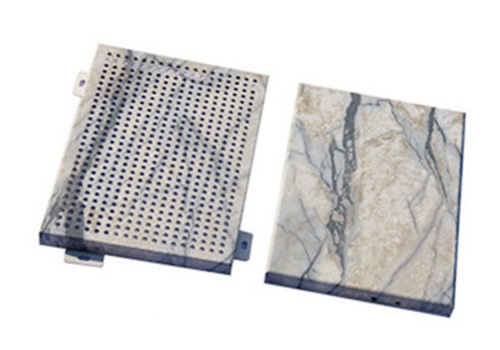

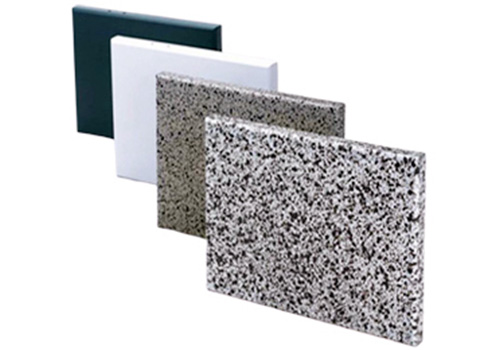

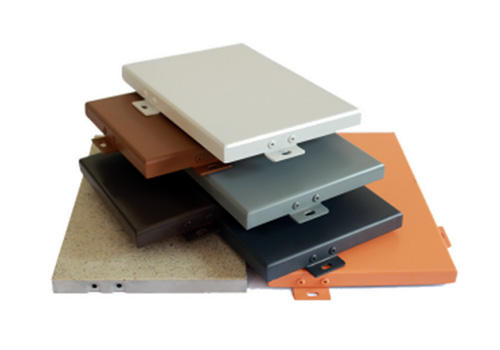

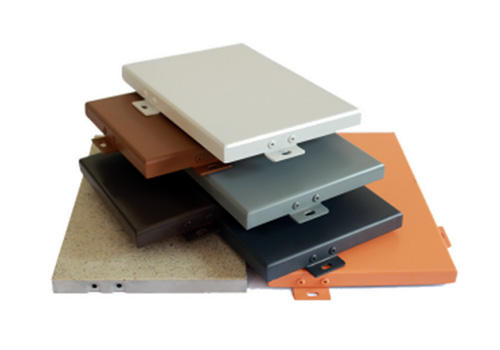

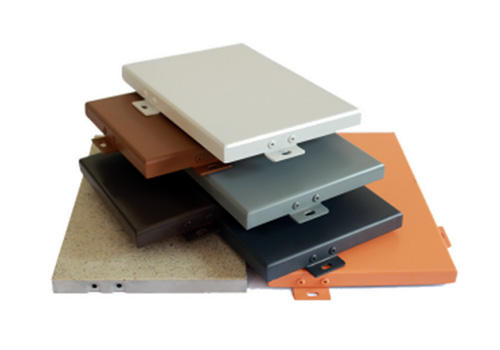

Aluminum veneer surface treatment processes include fluorocarbon spraying, powder spraying, polyester spraying, wood grain heat transfer, imitation stone paint, porcelain spraying, anodizing, wire drawing, pre-roll coating and so on. The surface coating of aluminum veneer can be customized according to customer requirements, the color can be modulated according to the template, and the company can also provide standard color cards for customers to choose.

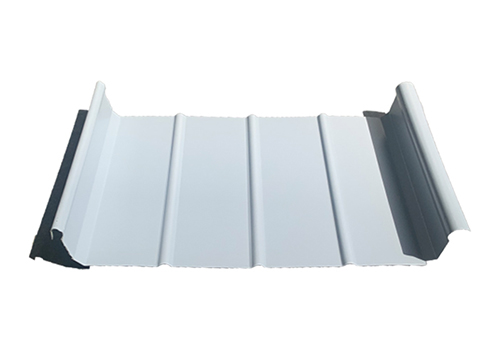

Fluorocarbon powder coating color selection is rich, there are bright, flat, dull, gloss to choose from, and sand grain, aluminum powder, pearlescent and other special effects for customers to choose.

The fluorocarbon spraying surface coating of aluminum veneer can be divided into two coats, three coats or four coats according to the processing technology, of which the average film thickness of fluorocarbon II coating is ≥30μm, the average film thickness of fluorocarbon III coating is ≥40μm, and the average film thickness of fluorocarbon IV coating is ≥65μm. Aluminum veneer powder spraying is one coating one baking, the average film thickness ≥40μm, the maximum film thickness ≤120μm.