Cracking, deformation, and paint peeling do not exist for aluminum veneers. Many friends will encounter a big problem with the decorative panels used in decoration. The good panels suddenly cracked, deformed, and peeled. How long have they been used? In fact, many decorative panels are prone to cracking, deformation, and paint peeling in summer. In fact, this is a very simple principle, which is the "thermal expansion and contraction phenomenon" mentioned in junior high school physics books. Therefore, outdoor curtain wall inspection and maintenance in summer are very important. However, these problems do not exist at all for aluminum veneers. In a humid environment, not to mention aluminum-plastic panels, steel will also rust. Direct strong sunlight can easily cause the paint on ordinary panels to fade, which is different from indoor panels. Once the paint fades, it will face the phenomenon of paint peeling, and the ability to withstand dirt will also decrease at the same time. Moreover, ordinary panels are special. Once they are really affected by this, it is difficult to restore them to their original state. So in summer, we can Avoid long-term exposure of ordinary panels to the sun. You can find a way to cover it to avoid various problems caused by exposure. But the problem is that the entire building uses ordinary panels for the exterior wall, so how to cover it becomes a difficult problem. The only good way is not to use it, and use aluminum veneer walls instead.

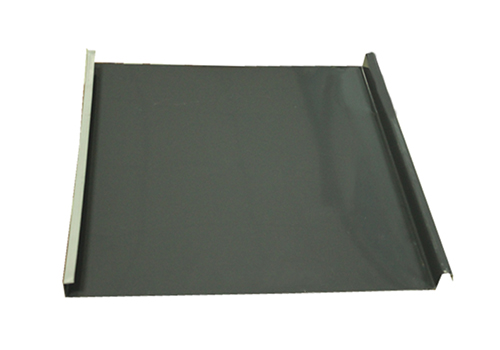

Aluminum veneers use fluorocarbon coatings, which have strong anti-corrosion and anti-fading and paint loss capabilities. For example: aluminum veneers are made of aluminum alloy, and the plate itself is very stable to high and low temperature performance, and has strong impact resistance, especially 3.0mm aluminum veneers can withstand stronger external impact. Aluminum veneer curtain walls are radiation-proof, corrosion-resistant, fire-proof, oil-proof, high-pressure-resistant, high-temperature-resistant, and low-temperature-resistant. Temperature, etc.

Cracks, deformations, and paint peeling do not exist for aluminum veneers

In addition to the characteristics of no cracking, no deformation, and no paint peeling, aluminum veneers are also lightweight, relatively rigid, and relatively strong. Aluminum veneers also have good flame retardant effects, and are more in line with fire protection requirements. Aluminum veneers are made of high-strength aluminum alloys and gas-carbon paint or panels. They have outstanding flame retardancy and can pass fire protection inspections.

Aluminum veneers are very good in terms of weather resistance, self-cleaning, UV resistance, acid resistance, and alkali resistance. They can effectively resist acid rain, outdoor air pollution, and UV corrosion. Aluminum veneers are made of a The special molecular structure makes it difficult for dust to fall on it, and it has excellent self-cleaning function. The aluminum veneer has good plasticity and can be processed into various complex graphics such as flat panels, curved panels and spherical panels, which can express the designer's various concepts. The aluminum veneer is colorful and has a relatively wide range of choices. It has rich visual effects and good decorative effects. The finishing coating of the aluminum veneer uses a matte coating, which not only maintains the internationally popular bright style but also solves the problem of light pollution of glass tomb walls. It is a rare and recyclable, green and environmentally friendly product.