With the more and more extensive use of aluminum veneer, the surface treatment process of aluminum veneer is also more and more rich. Common surface treatment processes are: fluorocarbon paint spraying, fluorocarbon powder spraying, wood grain thermal transfer technology, imitation stone paint spraying, anodizing process, metal wire drawing process.

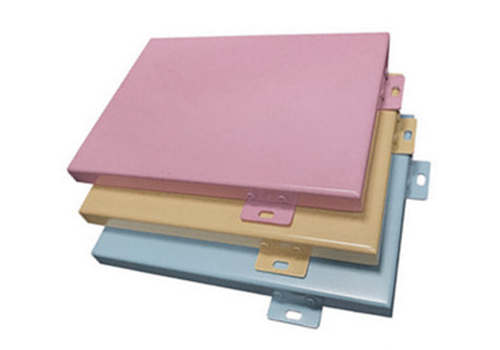

Fluorocarbon baking paint spraying

Fluorocarbon baking paint sprayed aluminum veneer weather resistance is very good, not afraid of high temperature exposure, acid rain and other harsh environment, used in the outdoor can also maintain more than 15 years without color, but also good resistance to ultraviolet radiation, is the preferred treatment of large building facade curtain wall.

Fluorocarbon powder coating

Fluorocarbon powder spraying can make aluminum veneer have good weather resistance, can have more than 10 years of service life, generally in indoor applications. Fluorocarbon powder spraying has the advantages of high efficiency, less pollution, high paint utilization rate, good film performance and high yield.

Wood grain heat transfer process

Wood grain transfer process by heating and pressurizing, the wood grain pattern on the transfer paper or transfer film is quickly transferred and permeated into the sprayed or electrophoretic profiles. Wood grain aluminum veneer texture is clear, three-dimensional sense is strong, wood texture image is vivid. Commonly used wood grain color are: walnut, beech, oak, elm, yellow pear wood, ebony, rosewood and other wood grain.

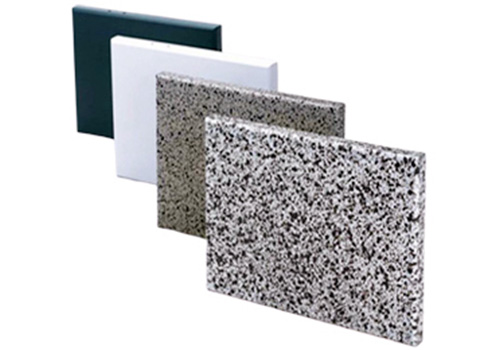

Imitation stone real stone paint spraying

Imitation stone lacquer spraying different colors of paint, patterns, after high temperature curing, attached to the metal surface, so that the aluminum veneer presents the visual effect of stone. Imitation stone lacquer not only has the visual effect of natural stone, but also has the advantages of thin, easy to install, high resistance and strong fire resistance, so that the building surface is more beautiful.

Anodizing process

Anodized aluminum plate is the process of generating a dense oxide film on the surface of the aluminum plate under the electrolyte solution, which is called surface anodizing. The anodic oxidation process can improve the corrosion resistance, surface hardness and wear resistance of the aluminum alloy sheet, and has a good decorative effect after coloring treatment. Anodized aluminum veneer is used as external wall decoration material for public buildings, commercial squares and sports venues.

Metal drawing process

Metal drawing is the manufacturing process of repeatedly using sandpaper to scrape the aluminum sheet out of the line, so that the aluminum sheet has both fashion and scientific and technological sense, which has become more and more common in life. The metal drawing process can not only play a beautiful and anti-corrosion role, but also make the design of the building have a special resolute beauty.